Back to top

Trusted by

services

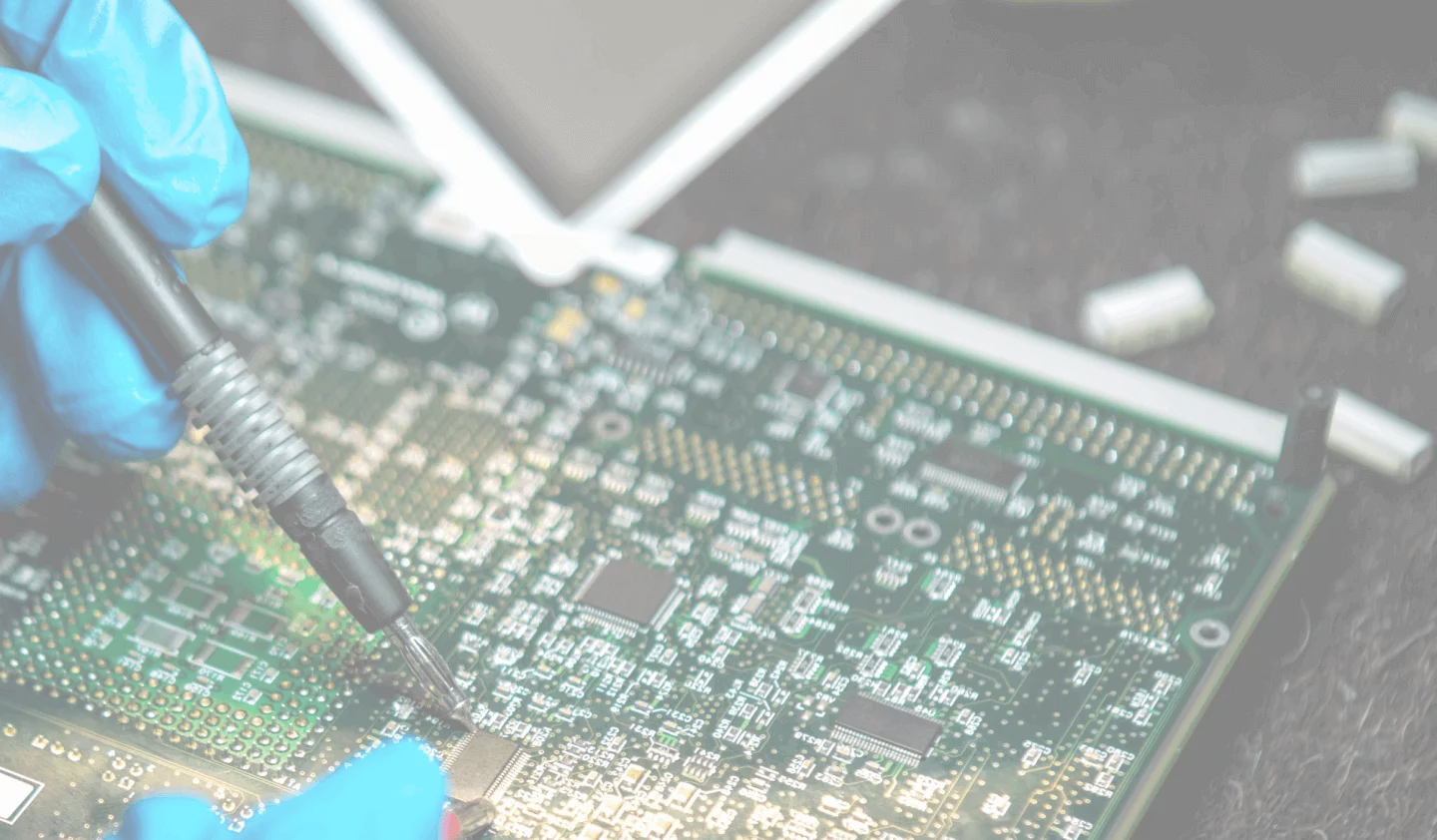

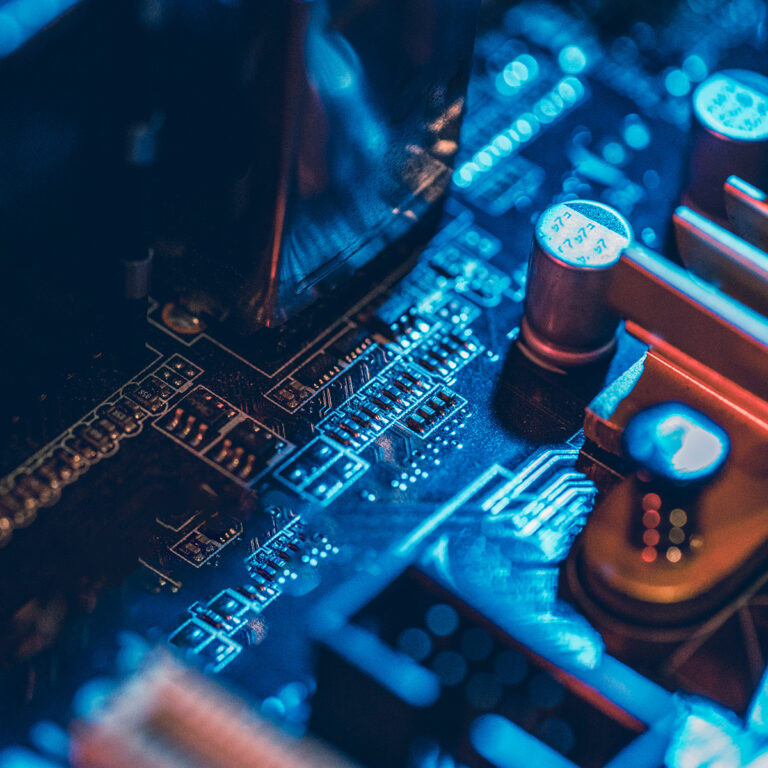

De-risk designs & deliver fast

We help electronics manufacturers design and develop complex systems through skilled expertise, flexible engagement models, and decades of experience.

portfolio

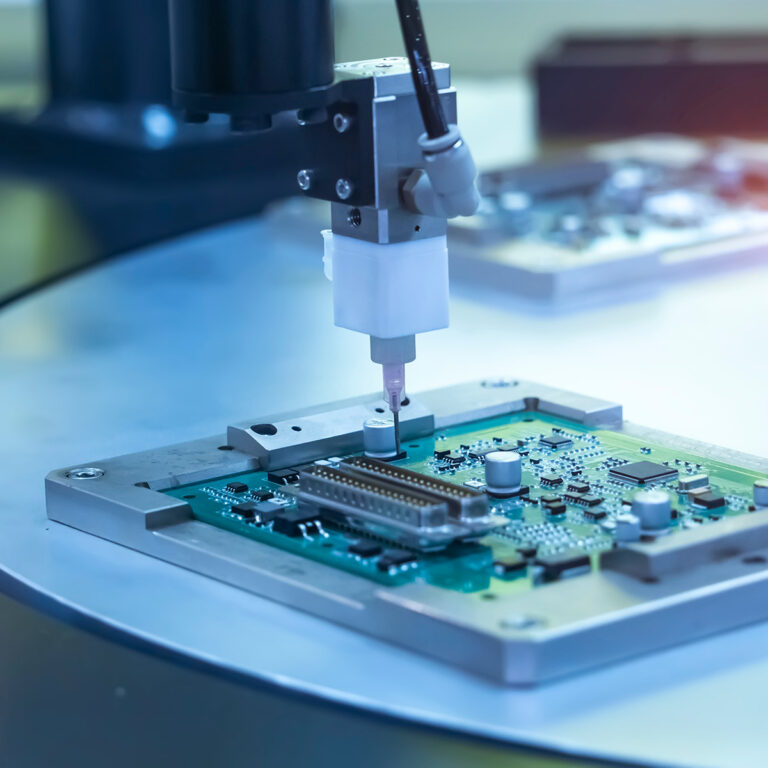

Transforming concepts into products

Explore our portfolio and see how we’ve transformed ideas, visions and concepts into customer products

Join our team

Explore our Resource Hub

A centralized resource hub for data sheets, case studies, whitepapers, webinars and more.

Learn more about the company

As technologies evolve, we continue to lead the transformation of innovative ideas into great products.

Discover more about Fidus

You have the vision. We have the team.

Trust us to deliver on time. That’s why 95% of our customers come back.